How precisely do the laser drilling machines that are used for mold precision differ from one anothe

Posted by Hazelwu

from the Technology category at

15 May 2023 09:23:39 am.

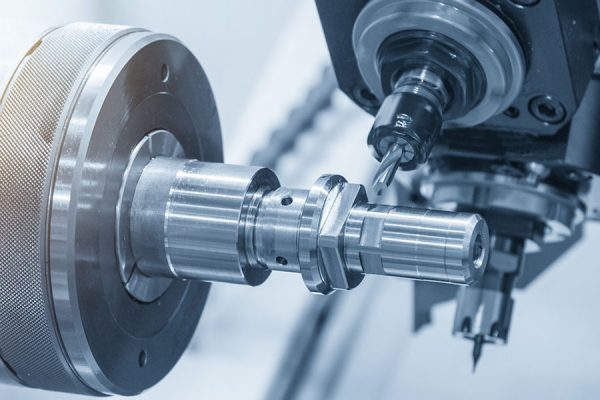

In recent years, the widespread adoption of laser drilling machines can be partially attributed to the fact that these machines are capable of resolving a variety of issues that are common in conventional machining. This is one of the reasons why laser drilling machines have become so popular. There is evidence that the mold was squeezed at some point in time, and if the stamping process is not carried out correctly, there will be deformation. There is evidence that the mold was squeezed at some point in time. It appears that the mold was squeezed at some point in time because there is evidence of this. It is guaranteed that the workpiece will not be damaged in any way because the high-energy laser beam dissipates instantly without coming into contact with the workpiece. The diameter of the mold's holes is typically anywhere from 0. 3 mm to 0 mm, with the vast majority of cases falling into the former category.

The laser drilling machine has an operation that is straightforward and easy to master, a processing quality that is of a high standard, a drilling speed that is extremely rapid, and a service life that is reliable over the course of a long period of time. The high-definition CCD vision system has the capability of being utilized for the positioning of the workpiece with high precision, which can meet the requirements of a wide variety of different kinds of materials. hole requirements. The laser drilling machine is able to punch any desired shape of hole after the necessary calculations have been completed on the computer to determine the size and shape of the hole. These calculations determine the size and shape of the hole.

An examination of die casting in aluminum alloys, including its benefits, drawbacks, and the range of possible applications

An examination of die casting in aluminum alloys, including its benefits, drawbacks, and the range of possible applications.

Die casting is a method of casting that involves pouring molten alloy liquid into a pressure chamber, filling the cavity of a steel mold at a high rate of speed, and then allowing the alloy liquid to solidify under pressure in order to form a casting. Die casting is a method of casting that was developed in the 19th century. The process of investment casting can also be referred to as die casting. Both the pressure and the speed have scaled new heights with their most recent measurements. The pressure of 15100 MPa is the one that is generally accepted as being the standard. It is possible to fill the cavity in a brief amount of time, approximately 0. 2 seconds; however, the length of time required for this process can vary based on the size of the casting. Die casting is a type of manufacturing that involves making use of three primary components in order to create the end product. These components are die casting machines, die casting alloys, and die casting molds. The so-called die-casting process is the organic comprehensive use of these three elements, which enables it to produce qualified castings that have a good appearance, good internal quality, and dimensions that meet the requirements of the drawings or agreements, and even high-quality castings. These qualities allow it to produce qualified castings that have a good appearance, good internal quality, and dimensions that meet the requirements of the drawings or agreements. Because of these qualities, it is able to produce castings that are qualified. Qualified castings have a good appearance, good internal quality, and dimensions that meet the requirements of the drawings or agreements.

When speaking of die casting, the fluidity of the alloy refers to the ability of the liquid alloy to completely fill the mold. This ability is discussed in relation to die casting. The eutectic alloy in the aluminum alloy can be worked with in a relatively straightforward manner due to the high fluidity it possesses.

In addition to its high cutting performance, excellent thermal conductivity, and excellent electrical conductivity, aluminum alloy possesses a number of other properties that are highly desirable. Additionally, there is very little shrinkage in aluminum alloy wire, which is another factor that contributes to the excellent filling performance of the material. This is one of the reasons why the material is used. The density of aluminum alloy is relatively low despite the fact that it possesses exceptional strength. Or, the excellent mechanical properties that it possesses do not suffer any kind of degradation in any way, even when it is used in an environment where the temperature is kept low. This material has a low level of hardness, and in comparison to other materials, it also has a low level of wear resistance. roughly 6. 8 percent closer to zero.

There are restrictions placed on the use of materials that have a high melting temperature but a low melting point. However, aluminum alloy bearings can be used in place of bronze bearings in applications that call for slow speeds, moderate temperatures, and heavy loads at a price that is approximately fifty percent lower than the price of bronze bearings. Furthermore, it can be used to produce profiles through continuous casting or centrifugal casting, which can then be used in the production of bearing bushes, bushes, and other similar components. These profiles can also be used in the production of bearing bushes. These profiles can also be used in the manufacturing of other components that are very similar to them. In addition to this, it can be utilized in the production of molds, as well as bearings, various pipe joints, pulleys, and other castings that are subject to impact as well as wear.

Tags: zinc alloy die casting

0 Comments