The industry needs of future slitting machines: automation, high precision, and multi-function

Posted by slittermachine

from the Business category at

07 May 2025 08:57:09 am.

1. Automation: Reduce manual intervention and improve production efficiency

Core Requirements

• Fully automatic loading and unloading: with robotic arm or AGV (automatic guided vehicle), it can realize automatic loading, slitting and unloading of coils

• Intelligent parameter adjustment: AI algorithm automatically optimizes tension, speed, and pressure to adapt to different materials

• Unmanned production: support automatic operation at night or holidays to reduce labor costs

Technology Trends

✔ Machine vision guidance (automatic recognition of web position, precise positioning)

✔ Internet of Things (IoT) integration (device connectivity, remote management from a central control room)

✔ Self-learning system (recording historical data for continuous optimization of cutting schemes)

Industry applications

• Packaging industry: reduce manual roll change time and achieve continuous production

• New energy battery separator: high cleanliness requirements to avoid artificial pollution

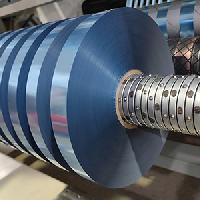

2. High precision: meet the needs of micron cutting

Core Requirements

• ±0.005mm ultra-high precision (e.g. optical film, flexible circuit board and other high-end materials)

• Zero-burr cutting (to avoid contamination or performance impact in the next process)

• Dynamic real-time web correction (to ensure that there is no misalignment during the slitting process)

Technology Trends

✔ Laser ranging + closed-loop control (real-time tool pitch adjustment)

✔ Air suspension turret (reduces friction and improves cutting stability)

✔ Nanoscale Servo System (Ultra-High Resolution Motion Control)

Industry applications

• Electronics industry (e.g. MLCC release film, FPC overlay film)

• Medical films (e.g. aluminium foil for pharmaceutical packets, dialysis membranes, which require contamination-free cutting)

3. Multi-functional: One machine can adapt to a variety of materials and processes

Core Requirements

• Modular design (quick-change tool set, adaptable to different materials)

• Multi-process integration (e.g. slitting + coating, slitting + inspection integration)

• Wide width compatible (200mm~3000mm width adjustable, reducing equipment investment)

Technology Trends

✔ Quick-change turret system (switch between different tools in 5 minutes)

✔ Multi-function workstation (integrated slitting, quality inspection, labeling, etc.)

✔ Flexible Manufacturing System (FMS) (for small batches, high-mix orders)

Industry applications

• Composites industry (e.g. carbon fiber prepregs, photovoltaic backsheets)

• Specialty paper (e.g. security paper, decorative film, customized slitting required)

A key technological breakthrough for future slitting machines

Industry case: the intelligent upgrade of an international film company

• Requirements: The production of high-end optical films, which requires an accuracy of ±0.01mm and supports multi-specification switching

• Solution: AI visual slitting machine + automatic tool change system

•Effect:

✅ The slitting accuracy is increased to ±0.008mm

✅ Format change time has been reduced from 30 minutes to 3 minutes

✅ The annual material cost is saved by more than 2 million yuan

The industry needs of future slitting machines: automation, high precision, and multi-function

conclusion

In the future, the core competitiveness of slitting machine will revolve around automation, high precision and multi-functionalization, and enterprises need to pay attention to:

? Intelligent upgrade (reduce manual dependence and improve stability)

? Precision manufacturing technology (to meet the needs of high-end material processing)

? Flexible production capacity (adapt to the trend of small batches and customization)

Only by keeping up with technology trends can we have an advantage in the future market competition!

Tags: slitting machine

0 Comments