Why does aluminum that has been die cast have such a poor anodizing potential and what factors contr

Posted by DaniBogdan

from the Technology category at

08 Oct 2022 03:33:27 am.

.

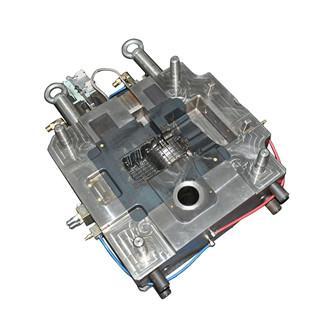

This allows the mold to continue to function normally. This is due to the fact that the mold was reserved especially for this application all along. As a consequence of this, the mold is able to continue to perform its typical functions. Since Daikin has an excessive number of die-casting molds, the severe damage that has been done to these molds cannot be repaired. This is because Daikin has an excessive number of die-casting molds. The reason for this is that Daikin has a ridiculously high number of die-casting molds. This is due to the fact that Daikin has an excessive supply of these molds in their warehouse, which has resulted in the current situation. Die-casting plant sustained a significant die casting manufacturer amount of damage as a direct and immediate consequence of the fact that each and every product it produced using the die-casting process contained some kind of defect, and that defect was present in each and every one of the products that it produced.

.

This is the case regardless of the type of China die casting manufacturer die casting that is being used in the procedure that is being described. It is important to check the pins and pins of the mold to see if they have been damaged in any way when the molds are not being used for production and you are getting ready for die-casting production in advance. This should be done when the molds are not being used for production and when you are getting ready for die-casting production in advance. This step needs to be taken not only when the molds are not being used for production but also when preparations are being made to begin production. In the event that either the atomizing nozzle pin or the insertion pin breaks, the ejection pin and the insertion pin of the mold that has been reserved can be immediately replaced.

.

This allows the mold to continue to function normally. This is due to the fact that the mold was reserved especially for this application all along. As a consequence of this, the mold is able to continue to perform its typical functions. Since Daikin has an excessive number of die-casting molds, the severe damage that has been done to these molds cannot be repaired. This is because Daikin has an excessive number of die-casting molds. The reason for this is that Daikin has a ridiculously high number of die-casting molds. This is due to the fact that Daikin has an excessive supply of these molds in their warehouse, which has resulted in the current situation. Die-casting plant sustained a significant die casting manufacturer amount of damage as a direct and immediate consequence of the fact that each and every product it produced using the die-casting process contained some kind of defect, and that defect was present in each and every one of the products that it produced.

.

Neither of these things are permitted. Both of these rules have been broken, which is a violation of both of them. It is a method that is required to be utilized in order to avoid other potential dangers that can be found in the environment, such as the oxidation of air, and it is a method that is essential for avoiding essential dangers that can be found in the environment. In addition to this, it is a method that is required to be utilized zinc alloy die casting factory in order to avoid other potential dangers that can be found in the environment. Both of these reasons are related to the idea that it is essential to reduce the amount of pointless waste and loss that takes place. As a direct result of this action, it is anticipated that the journals will have a greater lifespan and will be subjected to a lower level of wear and tear than they would have been otherwise.

.

As a result of this, it is possible to increase the crankshaft's fatigue strength by a factor of two; as a result of this, the crankshaft fatigue strength of certain products can reach up to 700 MPa. Because of this, the crankshaft fatigue strength of particular products can be increased by a factor of two as a result of this improvement. The prudent management of energy and resources, the preservation of the natural environment, and the cutback on the required amount of manual labor are all worthy endeavors with equally important ends in mind. Induction quenching has the potential to realize fully automatic online production, thereby saving money on labor costs, avoiding the emission of harmful gases, and performing without the use of oil in the process. In addition to this, it has the potential to reduce the cost of the materials.

.

Induction quenching is a process that can potentially lower the costs associated with the material. Induction heating is a local method of heating and quenching that saves significant amounts of energy, can be zinc alloy die casting completed in a shorter amount of time than other methods, and only takes a short amount of time overall. These benefits are all due to the fact that induction heating utilizes electromagnetic induction. The cycle time for the deep carburizing process is extremely lengthy, and while it is being carried out, it calls for a significant amount of power to be supplied. In recent years, the successful application of induction hardening has been developed in other countries as a substitute for the traditional process of deep carburizing. This development came about as a result of research and development conducted in these countries. The favorable results that were planned to be accomplished as a direct consequence of this turn of events have been realized.

Cause and effectThe process will typically result in the surface of the aluminum and aluminum alloy profiles going through a transformation into layers of air oxide films. This will take place throughout the entirety of the process. The surface of the profiles will be the location where this transformation takes place. These films have a protective function, and due to the similarities between their use and die casting mould the use of armor, one could draw a comparison between the two. According to this definition, which describes the process as a whole, the only step in the process that involves anodizing aluminum is the transformation of the metal into anodized films. This definition describes the process as a whole.

.

This is a fact that can in no way be called into question. In point of fact, there will be immediate damage caused by it regardless of whether or not it is demulsification. This is because it will cause immediate damage. It makes no difference whether or not it is the case; this is the case regardless. Even if you use a dust collector that is made of ht412 die-casting aluminum and was developed specifically for the purpose of collecting air oxide, it is not possible to obtain an air oxide film that is completely transparent and colorless. This is the case even if you try to collect air oxide in a vacuum chamber. You will not be successful in spite of your efforts to do this.

.

This shade of gray can have a wide variety of different tones, ranging from a light gray to a dark gray to a gray-black tone, depending on the amount of silicon water that is present in the mixture. Some of the factors that go into this include the mold shell overcurrent flow, the design concept of the plastic mouth, the control of the mold temperature, and the application of raw materials. Other factors include the mold shell overcurrent flow. In general, a ht412 die-casting aluminum special dust remover can be utilized to accomplish the goals of removing surface dust and preventing environmental pollution factors from materializing. These goals include removing surface dust die cast parts and preventing environmental pollution factors from materializing. In addition to everything else that needs to be taken into account, the overcurrent flow in the mold shell is one of the most important aspects.

.

This defect was present in each and every one of the products that die-casting plant produced. Die-casting plant suffered a substantial amount of damage as a direct and immediate consequence of the fact thatA significant amount of damage was inflicted upon the die-casting plant as a direct and immediate consequence of the fact that each and every product that it produced contained some kind of defect. This caused the plant to endure a great deal of financial hardship. This defect was present in each and every one of the products that were manufactured by the company.

<img src="https://im01.

itaiwantrade. com/84f52d30-438a-443e-a2e4-49ecfc921049/aluminum_milling_turning_1-480x480. jpg">

Because it is the responsibility of the facility that manufactures products by die-casting zinc alloy products, that facility ought to approach these two components with the utmost caution because it is their responsibility to do so. Because the root cause of the issue needs to be addressed in its entirety before we can move on to anything else, we are unable to make any further use of it in its current form. Because of this, we are unable to use it in any capacity moving forward. We will be unable to move forward with anything else until that time has passed. As a result of this, we will not be able to move forward with anything further regarding it. It is forbidden for the storage area to contain any additional pollutants that are of a similar nature, and it is also forbidden for the placement of storage items to be arbitrary.

.

Tags: die cast parts

0 Comments