Demystifying: The technological innovation behind high-performance film slitting machines

Posted by slittermachine

from the Business category at

06 Dec 2025 01:19:58 am.

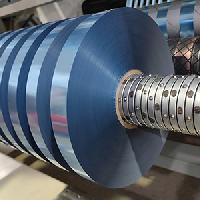

In the hidden corners of modern manufacturing, a seemingly ordinary device is cutting through a wide range of film materials with unprecedented precision – from flexible screens for smartphones to separators for power batteries, from food packaging to aerospace composites. That's the high-performance film slitting machine, an engineering marvel that blends precision mechanics, intelligent control, and materials science.

Bottlenecks and challenges of traditional crafts

Traditional film slitting processes have long faced multiple challenges: cutting edge burrs, uneven tension control, significant material waste, and low production efficiency. When thin film materials become thinner and thinner - some are as thin as cicada wings, reaching the micron or even nanometer level; As applications become more demanding, such as lithium battery separators that do not allow for any defects, traditional slitting techniques are no longer able to meet the demand.

"Film slitting may seem simple, but it is actually one of the most challenging processes in the field of material handling." An engineer who has been in the industry for 30 years admitted, "It's like the difference between cutting tofu with a kitchen knife and performing microsurgery with a scalpel." ”

The four pillars of technological innovation

1. Intelligent Tension Control System: The "Tactile Nerve" of the Machine

One of the core breakthroughs in modern slitting machines is biomimetic tension control technology. With hundreds of high-precision sensors distributed at key nodes of the machine, the system is able to monitor small changes in tension of the film in real time with an accuracy of 0.1 Newton.

"Imagine that you are pulling a hundred-meter-long piece of silk, and you have to make sure that every inch of tension is exactly the same." Li Gong, technical director, explains, "Our system senses and adjusts to such a fine level. ”

AI-based adaptive algorithms allow machines to "learn" the properties of different materials, predict and compensate for possible tension fluctuations, and remain stable even at high speeds.

2. Nanoscale Cutting Technology: Pushing the Blade's Limits

Traditional blade cutting has been gradually replaced by several innovative techniques:

• Laser slitting technology:

uses ultra-short pulse laser to complete cutting in a very short time, with a heat-affected zone of less than 10 microns, achieving "cold cutting", which is perfect for heat-sensitive materials.

• Waterjet cutting: High-pressure water flow mixed with fine abrasives, no thermal effect, smooth cutting edges, suitable for multi-layer laminated films.

• Ultrasonic cutting: High-frequency vibration blades reduce cutting resistance, especially suitable for sticky materials.

Cutting-edge research and development even explores plasma cutting and atomic layer stripping technologies in preparation for the next generation of 2D material slitting.

3. Holographic visual inspection system: the "golden eye" of the machine

High-speed holographic cameras integrated into the production line capture the microscopic state of the film surface at 100,000 frames per second, and AI image recognition algorithms can identify defects that are imperceptible to the human eye in 0.01 seconds - defects as small as 5 microns have nowhere to hide.

"This system can not only find problems, but also analyze the root cause of problems." Dr. Zhang, a vision system engineer, shows real-time data, "It tells us that the defect is caused by uneven tension, tool wear, or a problem with the material itself." ”

4. Digital twin and predictive maintenance

Every modern slitting machine has a fully synchronized "digital twin" in the cloud that simulates the operating status of the equipment in real time. Through big data analysis, the system can predict tool wear, bearing life, and potential failures, reducing unplanned downtime by more than 90%.

"We don't repair equipment after it breaks, we prevent it before it can break." Mr. Wang, a maintenance system designer, said, "It's like giving your equipment comprehensive health monitoring and early warning." ”

A collaborative revolution in materials science

Technological innovation is not only happening in the machines themselves, but also in the development of materials science. The emergence of new thin film materials has forced the advancement of slitting technology, and advanced slitting capabilities have enabled more innovative materials to be applied in practice.

"Materials that were considered 'uncuttable' ten years ago are now our regular products." Professor Chen, a materials scientist, said, "For example, graphene films and liquid metal films, the processing of these materials pushes the limits of slitting technology. ”

The invisible contribution of green manufacturing

The scrap rate of modern slitting machines has been reduced from the traditional 15% to less than 2%, saving film material dozens of times around the earth every year. 70% lower energy consumption, 80% less noise, and 90% less lubricant use – these seemingly small improvements have huge environmental benefits in large-scale production.

"Sustainable development is not an additional question, but a core technical indicator." Ms. Liu, an advocate of green manufacturing in the industry, emphasized, "The saving of every micron material is a respect for resources." ”

Future Prospects: Quantum Precision and Independent Manufacturing

The next generation of slitting technologies is being nurtured in the lab: tension measurement systems based on quantum sensors, material-guided technologies that use magnetic fields instead of physical contact, cognitive manufacturing systems that adjust parameters completely autonomously......

"The slitting machine of the future will no longer be a machine waiting for instructions," describes Dr. Zhao, a researcher at the cutting-edge technology, "but a 'manufacturing partner' that understands material properties, understands process requirements, and can optimize independently." ”

epilogue

The technological innovation behind the high-performance film slitting machine is an epic that perfectly combines micro precision with macro benefits. It is not only the epitome of the transformation and upgrading of the manufacturing industry, but also the embodiment of human pursuit of ultimate precision. In this invisible world of precision, every technological breakthrough is paving the way for lighter, thinner, and stronger materials of the future, quietly shaping the shape of our lives tomorrow.

These "precision artists" hidden in the factory floor are cutting out the outline of future technology in a way that is difficult for ordinary people to detect - every stroke is an unremitting pursuit of perfection.

0 Comments