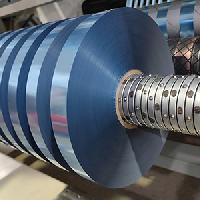

From PE to aluminum foil: multi-material slitting solutions for film slitting machines

Posted by slittermachine

from the Business category at

06 Aug 2025 01:50:50 am.

Slitting challenges for different materials

1. PE film

◦ Material properties: soft, highly ductile

◦ Main challenges: The edges are easy to stretch and deform, and static electricity is easy to generate

2. PET film

◦ Material properties: high hardness and good dimensional stability

◦ Main challenges: brittle edges and high slitting accuracy requirements

3. Aluminum foil

◦ Material properties: metal properties, non-ductility

◦ Main challenges: edge burrs, fast wear of slitting tools

Multi-material slitting solutions

1. Tool system optimization

• PE/PET: Use a circular knife for slitting with a knife angle of 25-35° to ensure a clean cut

• Aluminum foil: Uses carbide tools with a knife angle of 15-25° to reduce burrs

• Quick tool change system: Realize quick switching between different materials

2. Tension control system

• PE: Low tension control (5-15N) to prevent tensile deformation

• PET: Medium tension (15-30N) for stability

• Aluminum foil: high-precision micro-tension control (3-10N) to avoid breakage

3. Winding technology

• Surface winding: suitable for soft materials such as PE

• Center winding: suitable for hard materials such as PET

• Air expansion shaft winding: special for aluminum foil to prevent material deformation

4. Edge treatment

• Static Elimination System: Essential for PE/PET slitting

• Online monitoring: Detect the quality of the slitting edge in real time

• Burr treatment unit: special post-processing unit for aluminum foil

Equipment selection suggestions

1. Multifunctional Slitting Machines: Equipped with adjustable tool systems and tension ranges

2. Modular Design: Easy to replace key components based on materials

3. Intelligent Control System: Automatically recognizes material properties and adjusts parameters

Maintenance points

• Regularly check for tool wear, especially after handling aluminum foil

• Keep the working environment clean to avoid dust affecting the slitting quality

• Clean the equipment between different material slitting rooms to prevent cross-contamination of materials

With these solutions, modern film slitting machines can efficiently process a wide range of materials, from PE to aluminum foil, meeting the needs of high-precision slitting in different industrial sectors.

Tags: film slitting machines

0 Comments