From raw material to finished product: How does a film slitting machine achieve efficient and seamless slitting?

Posted by slittermachine

from the Business category at

02 Aug 2025 02:32:56 am.

1. Raw material preparation and pretreatment

• Material Inspection: Use laser thickness gauges or infrared scanning to detect film thickness, tension uniformity, and ensure no bubbles, impurities, or imperfections.

• Pretreatment: Adjust the ambient temperature and humidity (e.g., 25°C±2°C, humidity 50%±5%) according to the material characteristics (e.g., PET, BOPP, PE), and eliminate static electricity (<50V) if necessary.

2. High-precision unwinding control

• Constant tension system: using magnetic particle brake or servo motor, tension control accuracy up to ±0.5N (if the initial tension is set to 100-200N, adjusted according to thickness).

• Correction device: Photoelectric or ultrasonic sensor monitors the edge position in real time, with a correction accuracy of ± 0.1mm, avoiding serpentine belts.

3. Slitting process optimization

• Tool selection:

◦ Circular knife slitting: suitable for high-speed slitting (600m/min), insert hardness HRC60-65, angle 30°-45°.

◦ Razor slitting: used for ultra-thin films (< 10 μm), the knife edge gap is controlled at 0.5-1 μm.

• Dynamic adjustment: The online monitoring system (such as CCD camera) provides real-time feedback on the slitting quality, automatically adjusting the knife pressure (such as 20-50N) and angle.

4. Intelligent control system

• PLC+HMI: Preset slitting parameters (width tolerance ±0.05mm) to automatically match different material formulas.

• Big data analysis: record historical data (e.g. 500 slitting logs) to optimize process curves and reduce scrap rates (<0.3%).

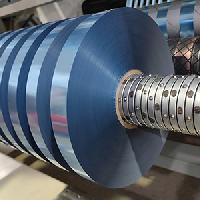

5. Winding technique

• Surface coiling/center coiling:

◦ Surface coiling for highly elastic film, contact pressure 50-80kPa;

◦ The central winding adopts servo motor, taper tension control (initial tension decrease by 10%-20%).

• Automatic reel change: The manipulator rewinding time < 3 seconds to ensure continuous production.

6. Quality inspection and feedback

• Online inspection system: Infrared scanner detects slitting edge burrs (<5μm) and rejects defective products in real time.

• Defect classification: AI image recognition systems distinguish between scratches, folds, and other defects, with a classification accuracy of > 99%.

7. Maintenance and upgrades

• Preventive maintenance: lubricate the guide every 8 hours and replace the tool every 500 hours.

• Modular design: quick-change tool holder (change time < 5 minutes) to support future upgrades (e.g. addition of laser slitting heads).

Key points for efficiency improvement

• Speed and Accuracy Balance: Maintains ±0.1mm slitting accuracy at 600m/min speed.

• Energy consumption optimization: The inverter motor saves energy by 30%, and the scrap recycling system reduces losses.

Through the integration of the above technologies, modern film slitting machines can achieve 24-hour continuous production, with a yield rate of more than 99.5%, meeting high-precision requirements such as photovoltaic backplanes and lithium battery separators. The core lies in the deep integration of mechanical precision, real-time feedback, and intelligent algorithms.

Tags: film slitting machine

0 Comments