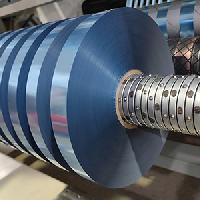

The core equipment of future film processing: the innovative direction of capacitor film slitting machine

Posted by slittermachine

from the Business category at

28 Jun 2025 01:58:22 am.

1. High-precision and ultra-thin cutting

• Nanoscale slitting technology: adapt to the cutting needs of ultra-thin films below 5μm, reduce edge burrs and stress damage.

• Dynamic tension control: Magnetic levitation or air bearing technology is used to realize nano-level dynamic adjustment of tension in the slitting process to avoid film stretching and deformation.

• Adaptive tooling system: Develop diamond-coated or ceramic tools that automatically adjust tool pressure and angle in combination with real-time wear detection.

2. Intelligence and digitalization

• AI Quality Inspection: Integrates high-resolution CCD and AI algorithms to identify film defects (such as scratches, bubbles) in real time and automatically sort.

• Digital Twin & Predictive Maintenance: Simulate the slitting process with a virtual model to predict equipment failures and optimize process parameters.

• Internet of Things (IoT) integration: Realize data exchange between equipment, support remote monitoring and intelligent scheduling.

3. Green manufacturing and sustainability

• Low energy consumption design: Servo motor and regenerative braking system are used to reduce energy consumption by more than 30%.

• Solvent-free slitting process: reduce contamination with traditional lubricants, develop dry cutting or environmentally friendly cooling technology.

• Waste film recycling module: built-in on-line recycling system for slitting edge materials, which can be directly crushed and recycled.

4. Flexible and multi-functional integration

• Modular design: quick switching of slitting width (such as 10mm-2000mm range adaptive), compatible with PET, PP, PI and other materials.

• Multi-process integration: Slitting and surface treatment (such as plasma cleaning, coating) are combined to reduce production links.

• Flexible coil handling: Adapts to laminated films (e.g. metallized films) with different hardness/thicknesses to avoid delamination or wrinkles.

5. Adaptability of new materials

• High-temperature/high-frequency material processing: Optimize thermal management for new energy vehicle films (e.g., high-temperature PC film) to prevent thermal deformation.

• Special-shaped slitting capability: non-straight line slitting such as curves and hollowing can be achieved through laser-assisted or waterjet technology.

6. Breakthrough in core components

• Ultra-precision spindle: speeds over 10,000 RPM and radial runout ≤ 1μm.

• Intelligent deviation correction system: real-time deviation correction based on machine vision (accuracy ± 0.1mm).

• Vibration suppression technology: The active vibration damping platform reduces the impact of equipment operating vibration on the film.

7. Standardization and data interconnection

• Open interface protocol: support seamless connection with MES/ERP system to achieve process data traceability.

• Industry standard setting: Promote the standardization of the matching between slitting equipment and film materials.

Application scenarios drive innovation

• New energy field: meet the needs of lithium battery separator with a large width (6m+) and high consistency.

• Flexible electronics: Adapt to the non-destructive slitting of brittle materials such as OLED base films.

• Military aerospace: develop special slitting environmental solutions that are anti-static and anti-pollution.

In the next 5-10 years, the capacitor film slitting machine will gradually evolve from a single processing equipment to an intelligent production unit integrating perception, decision-making and execution, and promote film processing into the era of "precision intelligent manufacturing". Enterprises need to focus on the integration and application of interdisciplinary technologies (such as materials science + robotics + AI).

0 Comments