Film slitting machine function award: high precision, high efficiency, leading film processing!

Posted by slittermachine

from the Business category at

24 May 2025 03:03:31 am.

First, the core function of the film slitting machine

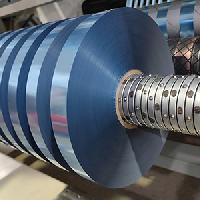

1. High-precision slitting

◦ Accuracy range: It can achieve a cutting accuracy of ±0.005mm or less, which meets the processing needs of ultra-thin materials (such as optical films, lithium battery separators, etc.) (such as less than 5μm).

◦ Technical support: high-rigidity servo motor drive + linear guide rail, with laser rangefinder real-time deviation correction, to ensure that the slitting edge is free of burrs and wavy lines.

2. Efficient production

◦ Speed performance: The slitting speed of modern models can reach 800-1200 m/min (such as lithium battery separator slitting machine), and some models are equipped with automatic roll change function to achieve 24-hour continuous production.

◦ Efficiency improvement: The double-station winding design reduces downtime and increases production efficiency by more than 30%.

3. Multi-material adaptability

◦ Compatible materials: Covers PE, PP, PET, aluminum foil, composite film, etc., and even can handle wet films (e.g. electrodes) after coating.

◦ Intelligent adjustment: Tension control system (such as PID closed-loop control) automatically matches the tensile coefficient of different materials to prevent deformation or breakage.

Second, breakthroughs in cutting-edge technologies

1. Intelligent control system

◦ AI visual inspection: real-time monitoring of slitting defects (such as scratches, bubbles), combined with big data analysis to optimize process parameters.

◦ IoT integration: support remote monitoring and predictive maintenance, with a fault diagnosis accuracy rate of more than 95%.

2. Energy-saving design

◦ Energy recovery: Some models adopt regenerative braking technology, which converts deceleration energy into electrical energy and feeds back to the grid, reducing energy consumption by 15%-20%.

◦ Low noise operation: Magnetic bearing technology makes the equipment noise less than 70dB.

3. Modular customization

◦ Plasma treatment module (to improve film surface adhesion) or dust removal system (cleanroom standard) can be selected according to requirements.

Third, industry application scenarios

• New energy field:

Lithium battery pole piece slitting (width tolerance ± within 0.1mm), separator ultra-narrow slitting (less than 1mm).

• Optical Films:

OLED display is slitted with optical film, which requires a dust-free environment (Class 1000 clean room adaptation).

• Packaging industry:

High-speed slitting of food-grade composite film (such as aluminum-plastic film) supports online waste edge recycling.

Fourth, the purchase of key indicators

1. Tension control accuracy: Models with ±1% tension fluctuation control are preferred.

2. Turret configuration: flexible combination of round knife (suitable for thick film) and air knife (suitable for thin film).

Future Trends

• Nanoscale cutting: to meet the demand for flexible electronics and ultra-thin graphene films.

• Digital twin technology: virtual commissioning shortens equipment delivery cycle by 30%.

The film slitting machine is redefining the limit of film processing through "precision machinery + intelligent algorithm", providing key support for the upgrading of the manufacturing industry. It is recommended that users choose the next-generation model with dynamic optimization capabilities according to material characteristics and capacity requirements.

Tags: film slitting machine

0 Comments