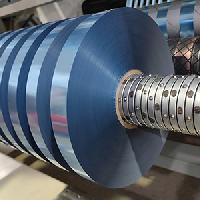

Metal foil slitting tool: the application of slitting machine in copper foil and aluminum foil processing

Posted by slittermachine

from the Business category at

09 May 2025 08:23:02 am.

First, special challenges of metal foil slitting

1. Material properties

• Extremely thin and fragile: The thickness of copper/aluminum foil is usually 6-20μm (even up to 4μm for lithium battery foil), which is prone to wrinkles and scratches.

• High ductility: The metal has strong ductility, and it is easy to produce burrs or curls during slitting.

• Electrostatic sensitivity: metal foil is prone to accumulate static electricity, which adsorbs dust and affects the subsequent coating/lamination process.

2. Process requirements

• Dust-free slitting: The dust particle size of the foil for new energy batteries is required to be ≤0.5μm (such as the slitting of the pole piece of the power battery).

• Zero-defect edges: burr height should be controlled at ≤1μm (to prevent short circuit in the battery).

Second, the key technology of metal foil slitting machine

1. Ultra-precision slitting system

• Tool design

• Nano-level cutting edge round knife: diamond-coated insert (3 times longer life) with a cutting edge arc radius ≤ 0.1μm.

• Air Float Support Turret: Reduces mechanical contact vibration and ensures cutting stability.

• Slitting mode

• Non-contact: laser slitting or ultrasonic slitting to avoid mechanical stress (suitable for 4-6μm ultra-thin foils).

• Rolling slitting: cemented carbide upper and lower knife to roll, pressure closed-loop control (accuracy ±0.01mm).

2. Dynamic control technology

• Multi-axis tension control

◦ Magnetic particle brake + tension sensor in the whole process of unwinding → traction → rewinding, with a fluctuation range of ≤ 0.1N.

◦ Taper tension to prevent sliding between foil layers.

• Real-time web correction system

◦ CCD visual detection of edge position, linkage with EPC correction mechanism (accuracy ±0.03mm).

3. Dust-free and anti-pollution solution

• Fully enclosed clean cabin

◦ Maintains micro-positive pressure internally, equipped with ISO Class 5 HEPA filtration.

• Static Elimination

◦ The combination of ionic air rod + conductive brush makes the electrostatic ≤ of 10V on the surface of the foil (new energy industry standard).

• Debris management

◦ Vacuum adsorption + electrostatic dust collection dual system, dust collection efficiency ≥ 99%.

Third, typical application scenarios

1. Lithium battery copper foil/aluminum foil slitting

• Slitting specification: width 100-800mm (suitable for battery pole piece size), speed 60-150m/min.

• Quality Requirements:

◦ No burrs (SEM detects edge roughness Ra≤0.2 μm).

◦ No oil stain (residue <0.01mg/m²).

2. Foil processing for electronic circuits

• High-frequency copper foil: The dielectric loss needs to be stable after slitting (e.g., RTF copper foil slitting accuracy ±0.02mm).

• EMI shielding aluminum foil: avoid lattice damage during slitting and affect shielding effectiveness.

Fourth, intelligent upgrade scheme

1. AI visual quality inspection

◦ In-line inspection systems (e.g., Keyence laser microscopes) identify defects such as pinholes and cracks in real time.

◦ Deep learning algorithms classify defect types (scratches/oxidation points, etc.), automatically mark them, and provide feedback on process adjustments.

2. Digital Twin Optimization

◦ Predict the impact of slitting parameters (e.g., tool pitch, speed) on quality through virtual commissioning.

Fifth, selection and maintenance suggestions

1. Key points of selection

◦ Ultra-thin foil (<8 μm) preferentially selects laser slitting or suspended mechanical slitting.

◦ Winders need to be equipped with surface defect detection (e.g., eddy current sensors).

2. Maintenance is critical

◦ Clean the knife holder and air duct daily, and check the tension system every week.

◦ The blade needs to be polished (or replaced) every 50 km of slitting.

Metal foil slitting machine is developing in the direction of ultra-thin, zero defect and intelligence, especially driven by the new energy industry, nano-level slitting and online quality inspection technology will become the core of competition.

0 Comments