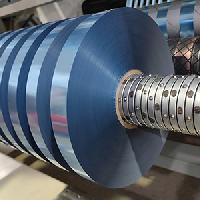

Technical analysis of high-precision slitting machine for label and tape slitting

Posted by slittermachine

from the Business category at

27 Apr 2025 07:16:12 am.

Core technical advantages

1. Micron-level slitting accuracy

◦ High rigidity linear guide is adopted, and the cutting accuracy can reach ±0.02mm

◦ Servo control system realizes nanoscale positioning

◦ The dynamic tension control system keeps the material stable

2. Intelligent deviation correction system

◦ CCD visual automatic edge alignment technology

◦ Real-time correction accuracy±0.1mm

◦ Correction parameters for a variety of materials can be memorized

3. Multi-functional toolholder design

◦ Round/flat knife quick switching system

◦ Pneumatic compression tool holder, pressure adjustable range 0-1.5MPa

◦ Automatic tool sharpening device extends tool life

Special feature configuration

1. Surface protection technology

◦ Non-contact slitting option (laser/ultrasonic)

◦ Anti-static ionizing air device

◦ Material surface dust removal system

2. Intelligent production management

◦ MES system docking function

◦ QR code traceability system

◦ Automatic yield statistics and loss analysis

3. Special material handling capabilities

◦ Slitting solution for ultra-thin materials (minimum 12 μm).

◦ Special anti-sticking treatment for high-tack tapes

◦ Low-tension slitting mode for fragile materials

Industry application performance

1. Label industry

◦ Die-cut label slitting with 0.2mm pitch

◦ Seamless slitting technology for transparent labels

◦ Continuous slitting of variable-size labels

2. Tape industry

◦ Double-sided tape is transferred and slitted without glue

◦ Slitting of high-thickness materials such as foam tape

◦ Stable production of narrow tape (1 mm width).

Equipment selection suggestions

1. Select according to material properties

◦ Ordinary self-adhesive: standard slitting machine

◦ Special adhesives: anti-stick configuration

◦ Metallized materials: Dedicated tooling system

2. Select according to the accuracy requirements

◦ Commercial grade: ±0.1mm

◦ Industrial grade: ±0.05mm

◦ Electronic grade: ±0.02mm

3. Consider expanding functionality

◦ The type of new material that may be produced in the future

◦ Automated loading and unloading requirements

◦ Data collection and analysis needs

These "secret weapons" of high-precision slitters enable them to meet the increasing quality requirements of the label and tape industry, while reducing the difficulty of operation and increasing production efficiency through intelligent functions, making them ideal for modern slitting production.

1 Comments

Comments

shemale sex dolls